Walker Hydraulic Jack Manual

This is a 1 1/4 ton hydraulic floor jack my father passed on to me. He bought it new during the 1970s. It began to leak down a little a few months ago. The lift arm no longer rises when the handle is pumped up and down. (I was able to pull the lift arm up by hand and it settled slowly enough that I could make a photo with the arm partially raised.)

I checked to be sure it was adequately filled with fluid, but that was not the problem. A few months before this problem, there were bubbles coming up through the vents at the filler plug. At that time I raised the lift arm with the handle, released the jack's valve, and let the arm fall slowly several times to purge air from the system. Finally, one day, the lift arm would not rise at all. If filling with fluid and purging air from the system do not restore function, there is probably internal leakage, even though fluid is not leaking from the jack. From what I have read, forty years of service is a reasonable time for a hydraulic jack to operate before it needs a rebuild.

A word of caution: Rebuilding this jack presented several challenges that seemed almost insurmountable at the occurrence of each. Rebuilding this jack was much more difficult than simply replacing a few 'O' rings, and it required more than the very few hours some say are required for rebuilding a jack. Further, I had to make several special tools to get the job done. If you want to attempt rebuilding a jack and you are not a member of Instructables, I would encourage you to pick a password and a screenname, and join. Doing that will allow you to download a PDF of this Instructable for printing, or to view at any time later on your computer, assuming you wish to consult what I have done as a guide.

When putting fluid into a jack never use anything other than hydraulic jack fluid. Starsat sr-x95usb super update free download. Do not use motor oil or brake fluid. Brake fluid makes the seals swell.

At this link you will find one man's description of how he rejuvenated his twenty-five year old jack by flushing its insides with a solvent, letting it dry completely, and filling it with fresh hydraulic jack fluid. It could be worth a try. I did find one manual for a floor jack that said the fluid should be changed every year. The procedure is to place the jack over a large pan, remove the filler plug, turn the jack on its side and let it drain. Then fill it again.

- Forum Actions

- Quick Links

I got a few links that didn't pan out, but I just ordered a parts breakdown from Hydraulic Jack Inc in New York. Info on old Walker Floor Jack.

Thread Tools

Display

- Aluminum

- Join Date

- Apr 2009

- Location

- Bartley,NE

- Posts

- 123

- Post Thanks / Like

- Likes (Given)

- 36

- Likes (Received)

- 27

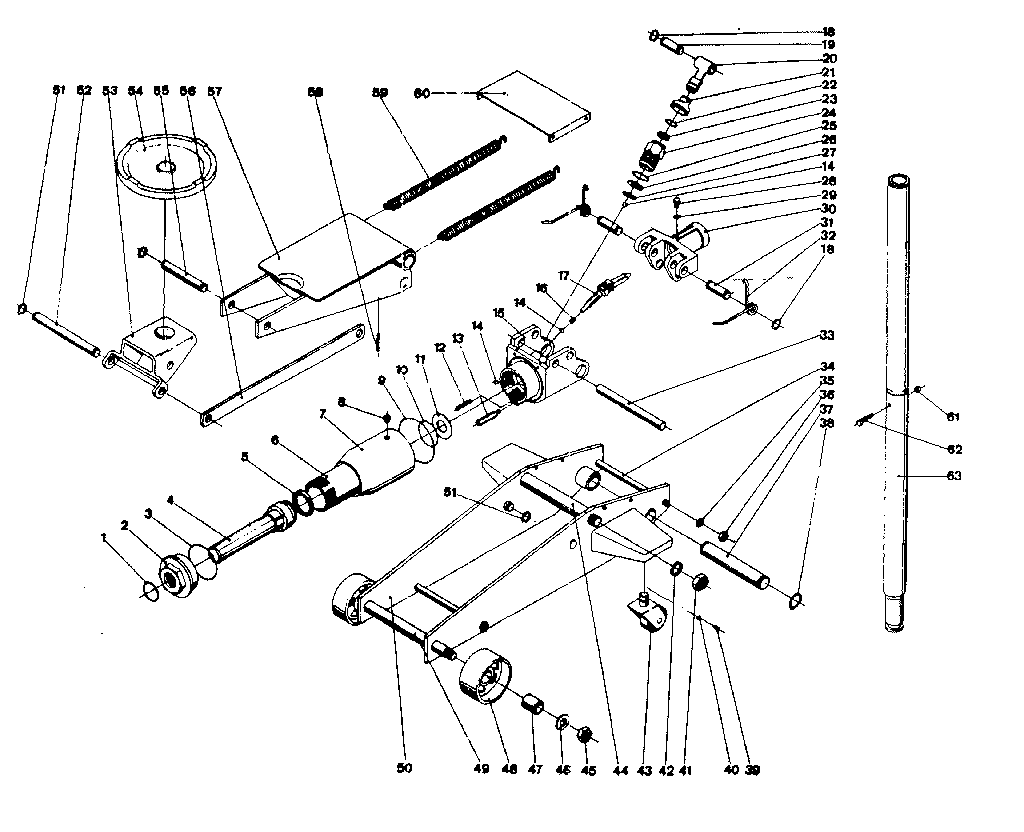

Need Walker floor jack schematics

Hey all,

I have a Walker model 93655 series K, 2 ton floor jack and am in need of a set of pictures of the blowup/schematics of this jack to take the pump apart and put it back together. I have a general knowlege of what I'm doing ...but that's about it.

Thanks,

Jim - Aluminum

- Join Date

- Dec 2007

- Location

- ne IL

- Posts

- 141

- Post Thanks / Like

- Likes (Given)

- 58

- Likes (Received)

- 15

Hello Jim, We have a walker about 10 years old, but we didn't get much with it except dumbed-down owner's manual, you know how to put the handle on, where to check oil, don't put on your foot while using, etc, etc, & list of authorized service places. Regards, Earl

- Diamond

- Join Date

- Sep 2005

- Location

- Connecticut

- Posts

- 4,436

- Post Thanks / Like

- Likes (Given)

- 529

- Likes (Received)

- 585

Is this the one you need:

http://www.panzittasales.com/PDFs/WA..56K_93657J.pdf

Steve - Hot Rolled

- Join Date

- Aug 2007

- Location

- Nashport. Oh

- Posts

- 780

- Post Thanks / Like

- Likes (Given)

- 10

- Likes (Received)

- 24

???

What is it doing?

You might get more help in the general forum. - Aluminum

- Join Date

- Jan 2008

- Country

- UNITED STATES

- State/Province

- New Hampshire

- Posts

- 200

- Post Thanks / Like

- Likes (Given)

- 34

- Likes (Received)

- 39

Walker J-132

Jarhead Jim,

Best thing to do is strip the powerunit from the chassis (separate side plates) and pull out the small pump piston out of the rear of the base (5/8'dia IIRC)...that's the most likely place the powerunit is junk (scores in cyl)...if the housing inside cleans up and polishes OK then keep going, the jacks probably salvagable...

When taking out the ball valves be carefull to arrange all valves and ball spacers in order to avoid a major mess..

A good repair kit should have new ball valves along with all seals to overhaul it right...

If you need a kit I may have one at work...I used to rebuild these routinely up until 15 yrs ago. and still have new/old stock left over..be glad to help if you need it...

Bill - Aluminum

- Join Date

- Apr 2009

- Location

- Bartley,NE

- Posts

- 123

- Post Thanks / Like

- Likes (Given)

- 36

- Likes (Received)

- 27

Thanks for the help fellas.

I took the pump apart and found the seal on the end of the main shaft was broken into many pieces. I cleaned the entire unit and kept all of the ball bearings and the such in one area. The 2' head nut on the pump was a royal bitch to get off but got 'er done. The handle is missing but I should be able to make one if I can't find one somewhere.

Jim - Aluminum

- Join Date

- Apr 2009

- Location

- Bartley,NE

- Posts

- 123

- Post Thanks / Like

- Likes (Given)

- 36

- Likes (Received)

- 27

Originally Posted by SteveMIs this the one you need:

http://www.panzittasales.com/PDFs/WA..56K_93657J.pdf

Steve

I'll have to get my little bro to download this as it is a pdf file and this computer won't do them.

Thanks,

Jim - Aluminum

- Join Date

- Apr 2009

- Location

- Bartley,NE

- Posts

- 123

- Post Thanks / Like

- Likes (Given)

- 36

- Likes (Received)

- 27

That's the one!Originally Posted by SteveMIs this the one you need:

http://www.panzittasales.com/PDFs/WA..56K_93657J.pdf

Steve

Thanks Steve!

Jim - precisionworksDiamond

- Join Date

- Apr 2005

- Location

- Benton, IL USA

- Posts

- 4,567

- Post Thanks / Like

- Likes (Given)

- 7

- Likes (Received)

- 46

Blackhawk is a good source for Walker parts: Blackhawkparts supplies repair parts for hydraulic jacks

(Enerpac repair kits also).

---------------

Barry Milton - Plastic

- Join Date

- Oct 2011

- Location

- Georgia, USA

- Posts

- 2

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

I have the exact same jack and need the whole shootin match to rebuild it..Bill, do you still have access to the rebuild kits that you mention from your work? It's in pretty good shape overall, just won't hold pressure on the piston from sitting for many years. I suspect all the seals are probably hard or broken up from age and non use. I'm going to completely dis-assemble it, grit blast and repaint everything, top to bottom. Please let me know availability and how much you would want for a kit that will do it all for the hydraulics..

Thanks, Don - Aluminum

- Join Date

- Jan 2008

- Country

- UNITED STATES

- State/Province

- New Hampshire

- Posts

- 200

- Post Thanks / Like

- Likes (Given)

- 34

- Likes (Received)

- 39

Drsamm,

There's a guy called Hiball on the 'Garage Forum' and he's the guru of jacks there....He fixes jacks and sells the kits you need

Here's a sample ..Old Sears Floor Jack 104 Prefix, Who Made It? - The Garage Journal Board

Though I haven't forgotten how to fix a jack, I don't have as many parts as I used to...Sorry - Plastic

- Join Date

- Oct 2011

- Location

- Georgia, USA

- Posts

- 2

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

Hey,

Thank you for the response..I haven't been able to sit down and check the site in a few days now, so sorry for my slow response. I occasionally get on the Garage Journal too, so I'll send him a message. Hope I have good luck with this old war horse. It's sound in every way, except for the leak, so it is well worth putting back right. The junk that's out there now can't compare in any way to this old USA made equipment! We can build ANYthing better and faster than anybody on earth, we just can't get the greed and government out of the way enough to do it any more..sigh.

DRSAMM

- Site Areas

- Forums

- Manufacturing Today

- Specific Machine Forums

- Open Discussion

- Commerce

- Machinery Manual, Brochure and Photo Archives

- Forum features

Walker Hydraulic Jack Parts

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off